-

Posts

157 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Events

Blogs

Downloads

Articles

Media Demo

Everything posted by viscoelastic

-

Run Time Errors

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I think so now also. When there was an issue I just assumed I was doing something wrong and someone was going to say; “you forgot to da da da da” and I would be on my way. Oh well, a quick call to the dealer and all shall be fixed. Thanks all for trying. -

Run Time Errors

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Ok, on a whim, I tried using the old fashioned phone cable and USB-Serial adapter and all works fine. I did not have any problem with my test V700 and USB cable only the V350 and USB cable. I think there is an issue with USB and V350's -

Run Time Errors

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I put it in boot mode by the long touch then the double tap. When its there, communications can't be established. -

Run Time Errors

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

-

Run Time Errors

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Morning Flex, No it was robooted several times. I checked the status in the PLC info page and it will show boot mode if it is in it. Thanks, Paul -

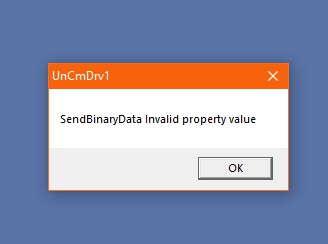

First time using a 350. If I try to download the program I get a Send Binary Data Invalid property value. So I tried to update the PLC and I get run time errors 380 then 440. Things I have tried: -Complete uninstall and folder removal as per instructions. -Multiple reboots -Updating PLC had the errors above -Prayed to the PLC gods -tried a V700 and it works fine -Checked my software version Version 9.8.65 Build 0 -Stopped yelling at my computer and talked nicely to my computer and the PLC -Ran as administrator -Tried a different cable and USB ports -Tried an empty program to send I am out of ideas and open for suggestions

-

CNC Router machine

viscoelastic replied to Rassgat5757's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I made a CNC router for my son. I would not look at a PLC for that task. Take a look at the Mach card and Mach 4 software is about $200. You'll have a easy to program machine without the pain. -

Value Fluctuation

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Thanks Guys! Now we have to get Joe Tauser to put up a profile picture with a smile in it. Right now he looks Grrr -

Value Fluctuation

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Hello all, Ausman, I have a millivolt generator and tried that also. So to put this thread to rest. This morning I found a V350 laying around and hooked the sensor to it. The reading is steady as a rock. So this defiantly comes down to I think I have a bad snap-in. -

Value Fluctuation

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Thanks Flex, I was thinking the same, but I figured I would bounce it off of people who are smarter than me before I dropped the dime. -

Value Fluctuation

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I also used a milliamp generator instead of a sensor. All results are the same. The reason I cant show less digits it because I am linearizing it to liters in tank. The result in an integer in 1 liter increments. -

Value Fluctuation

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Hey Flex, so is that normal then to have that much fluctuation? I have the filter set to high and it does not change it at all. The problem is that it makesthe linerarized number hard to read. -

Short Story: Reading 4-20mA raw number fluctuates as much as 60 points on 12 bit. When I put a milliamp clamp at the wire right into the V200-18-E4XB Snap in I have an absolute steady milliamp reading. Why does the raw value before linearization fluctuate so much with an absolute steady mA. Long Story Before I got a milliamp meter I kept changing wire, ultrasonic level sensors, laser level sensors and a milliamp generator to a set value. There have been posts in the past by me as I have been working through this issue of fluctuation. I always assumed it was something other than the PLC. Now I have trouble shooted everything back to the PLC and it is the unit that is creating the fluctuating counts. I am officially at the Grrr state of trying to solve this. Please help unGrrr me.

-

Shaft Encoder reload value

viscoelastic replied to meire's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Are you trying to write a batch? Say when it reaches 1000 or -1000 it does something? I can post an example if I know what you are trying to achive. -

Shaft Encoder reload value

viscoelastic replied to meire's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Can you post your code? -

Joe, I have ran into this before. It is something within the fine grained security of windows that wants to prevent a program from reading and writing to "mapped drives" you circumvent that by following the path. That being said there has always been an issue with visilogic and permissions. If they would get it certified by Microsoft a lot of issues would disappear. One Try running it as administrator and two turn off your uac and firewall and see if it lets you in, Keep me informed I am curious.

-

Meet in the middle

viscoelastic replied to JayC.'s topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

May I ask, are you using time/speed to determine distance? To be more accurate, have you thought about an encoder? -

Shaft encoder

viscoelastic replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I do not work for Automation Direct, but I buy a lot from them, and use their encoders. They have +24VDC encoders https://www.automationdirect.com/adc/Search/Search?fctype=adc.falcon.search.SearchFormCtrl&cmd=Search&searchquery=encoders&categoryId=829915&TxnNumber=-1&start=0#Product__F__Accessory_Type_ms="Rotary+Encoders"&start=0&rows=10&Input_Voltage_s="12+-+24" -

Upload error

viscoelastic replied to viscoelastic's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Hi Ausman, I tried what you said. It is intermittent. The only way I can get past it is by moving an object on the GUI slightly they it works.