Jamie123

Members-

Posts

31 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Events

Blogs

Downloads

Articles

Media Demo

Everything posted by Jamie123

-

Playing MP3 or WAV files are 4X normal speed

Jamie123 replied to Jamie123's topic in UniStream: Hardware

Just to close the thread. Support have said the MP3 needs to play at 192kbps -

Hello, I have been ask to add some audio instruction to one of my machines. I created an audio file using text to speech software. When the audio plays through the PLC it does so at 4X(guess) the normal speed. I tried both MP3 and WAV and tested the file on my PC and phone before hand. Has anyone experienced this before? Any fixes? Thanks, Jamie

-

Thanks for the replies. ORSO2001's method worked fine1.

-

Hello, I'm currently trying to read an encoder value from a drive via ModBus. The encoder value is split into higher 16 bit and lower 16 bit, hence I have to read two registers. Is there an easy way to combine the two values to get the single 32 bit value I'm after? TIA Jamie

-

VISLOGIC - PLC WATCHDOG

Jamie123 replied to BaToO's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I have made the changes as suggested and all is now well in the world. State machines are the way forward -

VISLOGIC - PLC WATCHDOG

Jamie123 replied to BaToO's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I found this thread to be relevant to a program I am currently writing. Programming PLC's is a tiny element of my job and I only do around 2 per year, hence why I am not particularly good at it! On my current program I have tried to use the state machine method - for the first time. Each state has its own sub routine(5 in total), the main program only calls the sub routine required based on the indexer. So each PLC scan consists of the main routine and one subroutine. The program has thrown out some weird behaviour (timers not resetting, coils remaining energized, cycle 1 works cycle 2 doesn't ) leading me to believe that running one sub routine at a time is not the correct way of implementing the state machine method. I then read this: Is the correct way therefore to call all subroutines in the main program and use the index coil to activate each rung of the subroutine you want to execute? -

Ok, I forgot to select "read" Dunce hat is on

-

Thanks Joe, I made a school boy error of which I am too embarrassed to mention.

-

Hello, I have almost successfully established Modbus communication with a servo drive. I say almost, I cant read the register but I cant write to them. I want to change the speed via a button on the HMI. I get a -11 on the stats tag which is timed out. Could someone please have a look at the ladder for sending the modus write. Have I missed something?

-

Comms with panasonic drive

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

-

Comms with panasonic drive

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I do have a contact at Panasonic but he is a salesman and doesn't have much technical knowledge. I have sent him an email to clarify the check sum value as I cant work it out either. I'll have a go at using the serial port monitor. -

Comms with panasonic drive

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

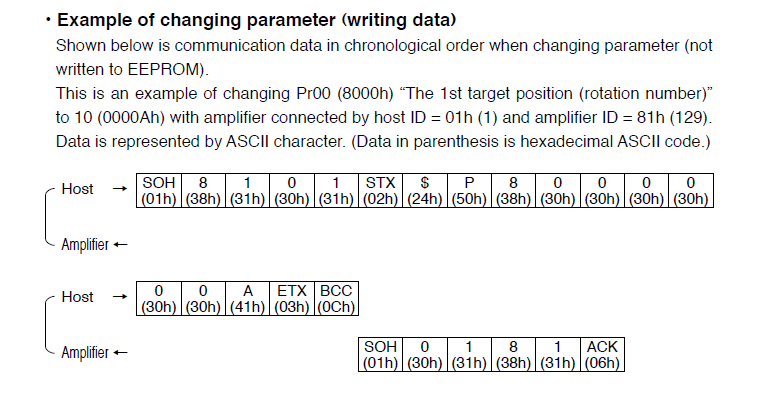

After another morning of getting nowhere with this, I have to as for help again. Could someone please show me what the protocol send and scan blocks should look like to mirror the lines in the picture. I don't want to continue trouble shooting until I have these blocks correct. Thanks in advance -

Hi Saragani, I have the latest version which is 1.23.25 A member of our IT team has had it running. It still wont open without requiring and admin login. As I work in a highly secretive industry, admin rights are very strictly controlled. They wont give one to a lowly engineer like me. Jamie

-

Hi All, I have just had UniLogic installed on my work laptop. Does UniStream only work if you run as admin? If so is there anyway round this as the company I work for only allow IT to have admin rights Jamie

-

Comms with panasonic drive

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Thanks Joe. I'll have another play this afternoon. -

Comms with panasonic drive

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I have had a bit of a play with this and have fallen at the first hurdle. I'm trying to replicate the read request command on the top of page 83. This is my first time using Protocol and I haven't a clue what I'm doing. Could someone please have a look at the screen shot and suggest the reason for the error message? Thanks -

Comms with panasonic drive

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Thanks Joe, I appreciate the help. -

Comms with panasonic drive

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Hi Aus Thanks for the reply! The drive operates in sequential mode and moves between 4 set points. Its a chemical dipping application and the speed between points 3 and 4 changes for different components. We can only change this speed by accessing the drive registers via a PC. -

Hello, I have been asked if its possible to establish communication with an on site PLC (v1210) and a Panasonic drive. Currently in order to change the drive parameters someone has to connect with a PC to make the changes and this has become a bit of a pain. All I need to do is read and write to two parameters on the drive. I had assumed that the drive had a comms protocol specific to Panasonic and therefore would be unable to establish a connection. I would be very grateful if someone could have a quick look at the comms chapter of the attached manual and let me know if its possible to establish comms with the PLC. Thanks in advance panasonic(vert xis).pdf

-

Hello, Could anyone recommend an encoder were the A and B can connect directly to the HSC. I can find any 24v encoders. Thanks

-

Samba Screen sensitivity

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

My sneakiness paid off. The operator likes to wear gloves 2 sizes too big to stop his hands sweating. You should have seen his face when I said I switched the PLC's. PS. he wasn't wearing baggy gloves when I was there.. -

Samba Screen sensitivity

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I have done something quite sneaky. I have been unable to replicate the fault, the button works for me every time, I suspect the operator has a bad aim. I have swapped the plc's without telling them. Will be interesting to see if the fault is then reported on the other machine. -

Samba Screen sensitivity

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

The screen protectors are still on both machines. I will remove them tomorrow. From watching the operator he only has one finger touch the screen. -

Samba Screen sensitivity

Jamie123 replied to Jamie123's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Yes I carried out a calibration, that's the only thing I could think of doing. Only one button would be pressed at a time. They are convinced the screen is faulty, but it works fine when I test it. -

Hello, I have two machines in operation that use Samba's. Both machines are identical. I have been having continued reports that the buttons on one of the machines fails to register on a regular basis, there have been no issues with the other machine. The screen has two large buttons on it. Every time I have been call out to fix this, the buttons work fine for me, the technician says the problem is intermittent and they have had no issues with the other machine. Is there a way to alter the screen sensitivity? How robust are these screens? Thanks in advance