-

Posts

3,271 -

Joined

-

Last visited

-

Days Won

238

Content Type

Profiles

Forums

Gallery

Events

Blogs

Downloads

Articles

Media Demo

Posts posted by Flex727

-

-

I've worked with dozens of V1210s over the years and had no problems, but recently I've gotten at least two V1210s that have touchscreens that require much more touch force than normal. One of them is quite excessive and in fact I thought the touch screen was inoperative as first. Is there something that can be adjusted for touch sensitivity on these PLCs?

-

9 minutes ago, MeriCummins said:

2) Will my recently downloaded version of Visilogic (9.8.95 bld 0) open the old project, allow me to edit, recompile and download it in to the PLC as-is without issue? It appears as though this should be no problem once I register.

Yes, but you will have to update the firmware on the PLC first. It's not difficult.

10 minutes ago, MeriCummins said:3) Registration says is required to up/down load use remote access etc. Do I need to be connected to the PLC when registering or is the registration strictly to the PC?

Registration is for the PC.

10 minutes ago, MeriCummins said:4) Since it appears as though the option to "burn" project was not selected when created-what is the reason one would not want to "burn" is burning just flashing a PROM on the PLC with the PLC program to be able to extract etc straight from the PLC via SD or otherwise? I would think that I will WANT to select the option to burn when I upload the revised PLC program.

Burn Upload Project allows anyone to upload the VLP file from the PLC. Most do not do that to protect intellectual property rights.

11 minutes ago, MeriCummins said:5) Are there any common pitfalls to avoid bricking the PLC? I have seen a couple forum messages and that is my biggest fear in trying to remedy a minor issue and losing complete function on this machine and not having any support.

It's almost impossible to brick these PLCs.

That said, here is what I recommend:

Download VisiLogic version 7.0.1 from the Unitronics website, or request it from Unitronics Support. Uninstall your version and install that (alternatively, install Version Swapper and download the Swapper version from the website and use 7.0.1 by swapping to it - that will allow you to use 7.0.1 without uninstalling 9.8.65. Then make your updates and download the update to your PLC.

It's not likely you will have a problem by using 9.8.95 and upgrading the firmware, but there is always a risk of some incompatibility when undertaking that.

-

1

1

-

-

-

-

I'm pretty proud of this one. This routine will run one of 20 recipes, each recipe can have up to 20 steps, and each step has 4 elements. The entire routine requires 13 ladder rungs - the operator merely selects the recipe and presses the run button.

It may not look like it, but it's actually a State Machine.

-

1

1

-

-

-

13 hours ago, Joe Tauser said:

Us old dogs have our feet firmly planted in ladder programming.

Yes, I really wanted the guy to ask more ladder logic questions.

Yes, ChatGPT is actually really amazing, but real AI it's not. I'm looking forward to future iterations.

-

Thanks for reporting back.

-

Stumbled on this and it's worth a watch. I think everyone here will find it interesting. Will our jobs be made obsolete by AI? Not seeing it in my lifetime (I'm old), but certainly eventually.

-

1

1

-

-

This forum does not contain a "Support Team". It is a user forum staffed by volunteer users, though a few Unitronics employees make an appearance from time-to-time. Unitronics support can be reached at support@unitronics.com. For a hardware issue under warranty you might also consider contacting your distributor for return or replacement.

Regarding your question, I haven't encountered that particular issue before but perhaps someone here has. Good luck.

-

41 minutes ago, kratmel said:

You can use two PWM PLC output for operate blue and red LED. 1-st start with 100.0% PWM duty on low temperature. Second with 0% on the same condition.

Both PWM can be operated by Linearization FBs. Input temperature - outputs PWM setpoints.

Nice solution, kratmel!

-

I probably should have put in rung comments:

Rung 1 - reset all 6 MBs

Rung 2 - Store 1 in the bit corresponding to the offset value of the random number MI

Rung 3 - turn on the correct output

-

Here is how I would do the part you are uncertain of:

You don't have to use vector functions - you can just use a series of compares - but this is easy and concise. You also don't have to group the elements in rung 3 the way I did with SB 1. I just like to group similar items in that way to save space and make for easier readability.

-

I just recently installed 9.8.96 and no registration was required. Thank you, Unitronics!

-

12 hours ago, guusminnaard said:

i don't know how I can transform the random number into an MB

This has no meaning. An MB is a bit - it is binary, either 0 or 1. A random number would be an integer, typically an MI.

-

Even without a State Machine (which I use almost religiously thanks to learning about it from Joe), it's not that difficult to write a program that allows things to restart gracefully since all operands are retained automatically. The programmer must be cognizant of any timers and power-ups, but it's not that difficult.

-

In VisiLogic, use SB 16.

UniLogic has the General.Touched Bit.

Both do the same thing.

-

51 minutes ago, MAL said:

That is dead code. That rung is only applicable to the v700. Its essentially a comment for this use.

Right-clicking and selecting "Disable" is normally how a ladder rung is turned off, but there are some elements that VisiLogic won't allow to be in a disabled rung. Sometimes I want to disable a rung with those types of elements for some testing or troubleshooting and never thought of doing this <insert headslap emoji>. Thanks for the tip, MAL!

-

1

1

-

-

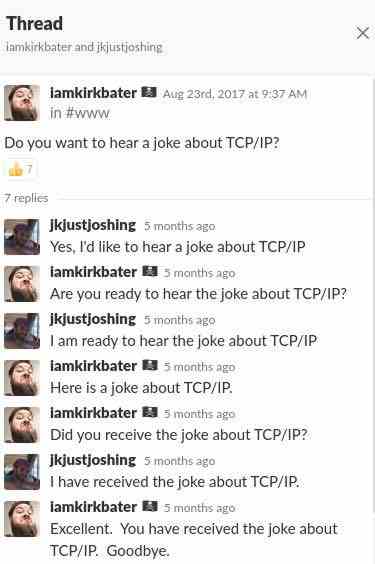

I'm more familiar with MODBUS than Protocol TCP/IP, but shouldn't there be slave addressing in your Protocol TCP/IP Configuration FB?

-

Hopefully you're aware of the vast differences between the way Ethernet works on a V700 vs a V1210.

Why is Socket 3 the only available socket? Have you confirmed that you have not duplicated port numbers on any of the sockets?

Are the PLC and server on the same subnet?

What communications protocol are you using?

Have you set up the connect logic properly? Can you post your program here for us to take a look?

-

1 hour ago, Joe Tauser said:

By also assigning port 502 to socket 3 without manually assigning something else to socket 2 we left the PLC in a position where it didn't know whether to shit or go blind.

Unitronics support always recommends initializing all 4 sockets at power-up even if only 1 or 2 are going to be used. This helps focus your attention on making sure there is no duplicate assignment. Do I do that? Rarely, but having all 4 default socket assignments memorized helps avoid the screwups.

-

3 minutes ago, Jreese37 said:

I'm not able to connect over ethernet to the PLC from PC.

Make sure the PC and PLC are on the same subnet. Note that your PC's wireless subnet will likely be different than the wired subnet.

-

I don't see anything wrong here. Are you able to connect to the PLC from a PC? Are you able to connect to your peripheral from a PC? Have you double-checked all IP addresses and port numbers? I see that you are using port 502 in the PLC and the peripheral. Nothing wrong with that, but just checking. Are you sure the peripheral is set up to be a MODBUS slave on port 502?

I see in the comment that the slave ID MUST be 255. In my experience I haven't found that to make a difference, but you have ID 254.

What happens when you try to connect? When you're online does SB 150 come on, even briefly? Does MB 0 come on briefly? Does MB 4 immediately reset?

Just this morning I was fighting with a PLC that wouldn't connect with MODBUS. I was ready to pull my hair out until I replaced the Ethernet cable. The cable was relatively new and was just recently working. Make sure you troubleshoot the ENTIRE connection, including cables, hub, etc. If you're not using a hub, are you using a crossover cable or adapter?

-

27 minutes ago, Jreese37 said:

This line in the comments says "Below, both Ethernet card initialization and MODBUS Configuration are done as Power-up tasks.

Note that Socket 2 must be initialized, via the Socket Init FB, to function as a TCP Master. Network ID number MUST be 255!"I noticed that it is set to socket 3 in the demo file, and also set to client, along with the MODBUS IP CONFIG function block socket is set to 3. I had seen in some prior documentation that some were using different socket numbers there in the initialization rung. I was highly confused about how that could ever possibly work?

Sockets are just defined pathways to specific ports. You can use any of the 4 sockets interchangeably as long as you have initialized them correctly and don't have 2 with identical settings. Each of the 4 sockets have a default initialization, but can be changed at any time (normally at start-up) with a socket initialization function block. The fact that the rung comment and the following ladder rung don't match is just a typo in the comment. Of course, the socket number must match in the initialization FB, MODBUS configuration FB, TCP connect FB, and the MODBUS read or write FB.

33 minutes ago, Jreese37 said:I'm a bit confused as to how the hex conversion in Visilogic works, if I enter a 3 into the Start of vector box, and set to hex, it doesn't appear to be giving me the actual value for 3(0x0003.) Although I don't suspect this matters whether I enter it there as hex or decimal?

I'm not sure what you're expecting here, 3 is the same in both hex and decimal. Enter a number greater than 9 if you want to see a conversion.

1040V(A) HMI Visilogic-EDITING BASICS minor eng unit scaling change to OLD code and recompile and upload with newer Visilogic version

in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Posted

This is always wise, but FYI for OP - standard download should not disturb operand values.