-

Posts

3,325 -

Joined

-

Last visited

-

Days Won

241

Content Type

Profiles

Forums

Gallery

Events

Blogs

Downloads

Articles

Media Demo

Posts posted by Flex727

-

-

One of the nice things about Unitronics PLCs is there are several ways to communicate with them from your computer. Tell us exactly what method you are using, what type of cable, what version of Windows you are using, etc, and someone will help you troubleshoot.

One other thing, mind if I ask why you would attempt to use the BETA version of the software, rather than the released version, if you are new to the software?

-

It's a hand that's lost its thumb because it didn't have a Unitronics control system for some dangerous equipment?

-

1

1

-

-

16 hours ago, kratmel said:

The customer's request is to ensure that even a power cut is recorded as an alarm, but only when it exceeds 15 minutes.

Then Ausman's suggestion should work just fine.

-

4 hours ago, Ausman said:

............so thanks for helping, Flex.

-

And SB 2 should be a contact, not a coil.

-

Well, first of all, SB 58 should be a Positive Transition contact, not a direct contact.

-

Just use the Data Tables Find Row function block. It sounds like it will do exactly what you want.

-

Moved to the correct forum.

-

Did you create a Fonts and Images file from the PLC and then select it to be used?

-

16 hours ago, Lacey said:

I need to read multiple Modbus registers from a non Unitronics controller. These registers are not consecutive registers. What is the best way to do this? Multiple Read Holding Registers (3) one after another? Rung examples of your ideas would be most helpful and appreciated.

Unitronics MODBUS communications are very forgiving in my experience. If the registers are non-consecutive, but not too far apart it's probably easier to read the entire vector that encompasses the data you want and then select what you need via ladder (as Ausman suggests above). If the registers are too spread out (total vector >120 registers) then you can certainly do consecutive reads. If there are a large number of them, then set up timers to read them individually, but if you just need a small number read, they can be read in the same cycle. The example below shows both a read and write in the same PLC cycle (using MODBUS TCP/IP). The second one just waits until the first one is complete (due to MB 20).

If you're not sure, just try it - you won't break anything.

-

2 hours ago, Lorenzo said:

Hello everyone, I wanted an information if the Visilogic software also makes the program PLC V130-J-T38.

This is Google's Italian translation which is not clear. Perhaps this is the question: Is VisiLogic used to program the V130-J-T38 PLC. The answer to that is YES. -

-

A little bit of advice - if you hit an impasse, just try different things - you won't break the PLC. Make your best guess, implement, then go online with the PLC and see what is happening. If that doesn't work, make an adjustment and watch what happens. You'll home in on the solution eventually. No one always knows how to solve a logic problem on the first go.

-

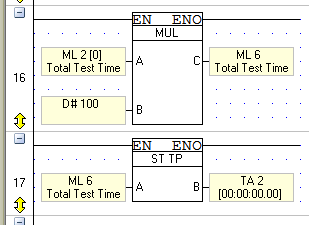

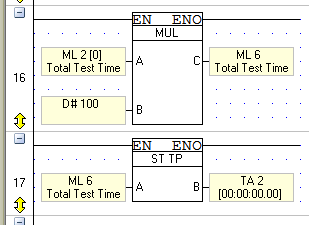

No time right now to analyze your logic, but I'll quickly show you how I do #1:

Also, you need to change the timer display to Preset and adjust the Format:

If your Total Test Time will exceed 24 hours, you'll need to do a bit of math to separate out and display the number of days.

-

Also, if you want to get rid of that compile warning about SB 168, SET the Power-Up value on the operand itself instead of using SB 2 in ladder.

-

15 minutes ago, C_R_PLC said:

In INFO mode I am not seeing a way to reset the PLC or STOP the PLC, is there something I'm missing with that?

Go to "Working Mode".

-

I loaded up your two latest programs into two PLCs I have here in my office and it seemed to work perfectly. I would suggest, however, that you add an inverted contact of SB 150 in series with the other contacts in your Master Connect ladder rung (rung 6).

-

In your Master program your MODBUS Config and MODBUS Read DT you are identifying the slave IP address as 172.16.0.0, but your slave is 172.16.0.1.

Also in your Slave program, delete the line from your MODBUS config (Index 0) where you identify a slave IP address - that's what gets entered into the Master config, not the Slave config. It probably just ignores it, but delete it anyway.

-

I'm going to hit up @Cara Bereck Levy one more time just in case she missed it. It looks like the Timers Help section was lost in the update to 9.8.79. Didn't this happen once before?

-

2 hours ago, Roho said:

It's working!

Ah yes, the phrase every programmer longs to hear.

-

49 minutes ago, Roho said:

you hit stop when the motor is off and the off timer just keeps on going

I presume that the only reason you care is that next time you hit START you want it to stay stopped until the off timer completes the previous cycle. If that's the case, given the logic you currently have in place, it looks to me like the easiest way would be to add a latch bit that indicates the status of the last press of the start or stop button, as follows:

-

Uh oh, is this a problem with Windows updating something? Try to re-install the driver for your USB to serial driver.

-

2 hours ago, Roho said:

I'm sorry to bother ya'll, I'm just fumbling my way through this and realized a little help would be necessary. Thanks for any and all help you can give.

Help is what we're here for, especially when you're attempting to work your way through it and not just asking for someone to write your program for you. I'm not sure why the Timer section of the help file got lost, but I'm sure Cara will get it fixed. I recommend not using the Beta version of the software for your first program.

Were my suggestions on how to deal with the timer issues clear? I'm attaching a pdf of the Timers section from a previous version of VisiLogic that should help you understand the 3 different types of timer that VisiLogic offers. While it's fewer than the 15,000

different types A-B offers, these 3 (TD, TE, & TA) WILL get every job done with some careful thought.

different types A-B offers, these 3 (TD, TE, & TA) WILL get every job done with some careful thought.

-

@Cara Bereck Levy, I just noticed that the entire topic of Timer operands has disappeared from the Help file for VisiLogic 9.8.79. Can you look into this?

@Roho, note that I made a small edit to my answer, changing TE to TA.

Unitronics Logo

in The Lounge

Posted

We're going to hold you to that!