-

Posts

3,261 -

Joined

-

Last visited

-

Days Won

236

Content Type

Profiles

Forums

Gallery

Events

Blogs

Downloads

Articles

Media Demo

Everything posted by Flex727

-

Visilogic timer project

Flex727 replied to Roho's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

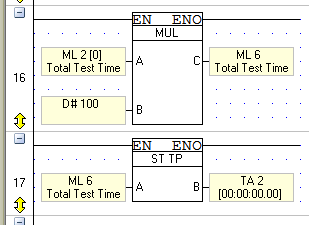

No time right now to analyze your logic, but I'll quickly show you how I do #1: Also, you need to change the timer display to Preset and adjust the Format: If your Total Test Time will exceed 24 hours, you'll need to do a bit of math to separate out and display the number of days. -

In your Master program your MODBUS Config and MODBUS Read DT you are identifying the slave IP address as 172.16.0.0, but your slave is 172.16.0.1. Also in your Slave program, delete the line from your MODBUS config (Index 0) where you identify a slave IP address - that's what gets entered into the Master config, not the Slave config. It probably just ignores it, but delete it anyway.

-

Visilogic timer project

Flex727 replied to Roho's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I'm going to hit up @Cara Bereck Levy one more time just in case she missed it. It looks like the Timers Help section was lost in the update to 9.8.79. Didn't this happen once before? -

Visilogic timer project

Flex727 replied to Roho's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Ah yes, the phrase every programmer longs to hear. -

Visilogic timer project

Flex727 replied to Roho's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I presume that the only reason you care is that next time you hit START you want it to stay stopped until the off timer completes the previous cycle. If that's the case, given the logic you currently have in place, it looks to me like the easiest way would be to add a latch bit that indicates the status of the last press of the start or stop button, as follows: -

Visilogic timer project

Flex727 replied to Roho's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Help is what we're here for, especially when you're attempting to work your way through it and not just asking for someone to write your program for you. I'm not sure why the Timer section of the help file got lost, but I'm sure Cara will get it fixed. I recommend not using the Beta version of the software for your first program. Were my suggestions on how to deal with the timer issues clear? I'm attaching a pdf of the Timers section from a previous version of VisiLogic that should help you understand the 3 different types of timer that VisiLogic offers. While it's fewer than the 15,000 different types A-B offers, these 3 (TD, TE, & TA) WILL get every job done with some careful thought. Timers.pdf -

Visilogic timer project

Flex727 replied to Roho's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

@Cara Bereck Levy, I just noticed that the entire topic of Timer operands has disappeared from the Help file for VisiLogic 9.8.79. Can you look into this? @Roho, note that I made a small edit to my answer, changing TE to TA. -

Visilogic timer project

Flex727 replied to Roho's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Just a little bit of time to devote to this right now. I'll try to help more later. I would not use a timer for this, merely increment a register every second of run time (or use SB 7 if you need more precision). You can then manipulate MI 0 (oops, I see now that I mistakenly used MI 0 instead of ML 0, which would be less likely to overflow) to display on the HMI in various ways or use for calculations. If you need timers to pause and not reset, then change your logic to use TA timers instead of TD timers, or use an incremented register or counter as I did above for the total run time. -

An invitation to suggest ideas for new UDFB's

Flex727 replied to Eyal Koren's topic in UniLogic Software

Most minor changes do not require the PLC to stop and the software will warn you if it needs to. -

Issue with displaying a MI

Flex727 replied to PaulZ's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

Excellent response from Ausman. I'll add one more thing in the interest of good programming practice - do NOT have conditional subroutine calls. In rung 16 of the Main Routine, the direct contact of MB 4 is totally unnecessary. There's nothing wrong with separating out your button check into a separate subroutine if you wish, but there's no reason to only call it when that screen is displayed. Same with rung 17, and also in rung 18. Rung 18 isn't a conditional subroutine call, but MB 6 is totally unnecessary. If you want all that stuff in one ladder rung, then replace MB 6 with SB 1. Regarding the incorrect display of MI 3. That is only occurring when you have the Trend graph displayed. And it's not being displayed incorrectly - MI 3 is being overwritten by the value "1" when the Trend is on screen. I don't have time to go through your Trend graph setup in detail, but look there for your problem. Perhaps delete it and re-create it if you can't find the issue. -

Only when there is an actual I/O module attached to the PLC.

-

That allows you to change the value when you're in online mode.

-

By the way, the answer to your question, @JOYE, is that FACTOR is how you deal with the decimal placement since you are converting the string representation to an integer. If the string looks like this: "123.45", then you would use a factor of 100 to result in an integer value of 12345. You can then display this integer number on the HMI screen and identify where to place the decimal. If you use the number in calculations, you would need to account for the fact that the number has been multiplied by 100 and deal with that properly.

-

@Cara Bereck Levy, as far as I can tell, there is absolutely nothing on this function in the help file. Can you help?

-

Setting RS485 Parameters

Flex727 replied to MisterB.Ohio's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

I think Ausman is correct here. You could set up multiple pre-set configurations for the user to select and have the selected configuration initialized by ladder. I haven't tried that, but it should work. -

No. You need to load the project in a PLC to simulate. You don't need to have any of the I/O modules though.

-

Moved to the correct forum. Please don't make duplicate posts. This board is moderated therefore it can take a bit before posts are approved. I'll leave this up since it includes more detail than the previous one.

-

Moved to the correct forum.

-

Time Delay not-correct

Flex727 replied to GenXMeds's topic in Vision & Samba PLC + HMI Controllers & VisiLogic Software

@GenXMeds, email me your program along with a description of what you're trying to do and what isn't working and I'll try to help (I have 9.8.79 installed and it seems to work on my computer). I'll also post it here for you if you like. Email to: blanier at arc-controls dot com.